01、Auditing drawing

In aiming for coordination drawing and production, Rongguan set up the design department and equip it with professional designer who is responsible for project

and further drawing.

The designer must verify the size when receiving the drawing. Inch size should be translated first for the export project, then make a Auto CAD drawing.After client's confirmation to i, the processing details of counter top will be discussed further more.

If sink should match up with countertop, the designer must arrange a drawing and counter top sample according to client's sink sample which is received, take photos also as record. When every thing is confirmed, the production starts.People of design department will follow the whole process production and take pictures for client's confirmations, to ensure the good quality as per client's demands.

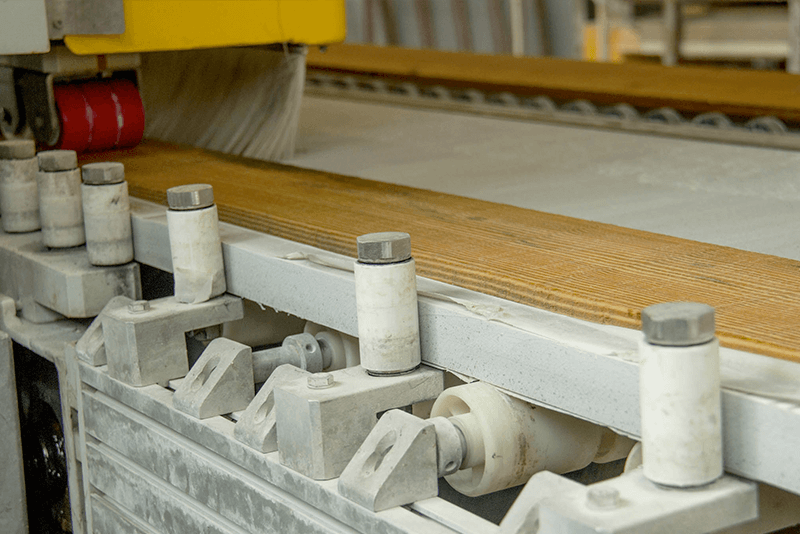

02、 Cutting to size

Before cutting slabs, the order list should be calculated by a software to result in the best cutting scheme by which the slabs will be cut to customized size on the machine then.

Rongguan cut slab by CNC cutting machine with infra-red positioning system, controlled by computer, to ensure the accuracy of linear size, corner and catercorner, to avoid any damage to size or corner during cutting.

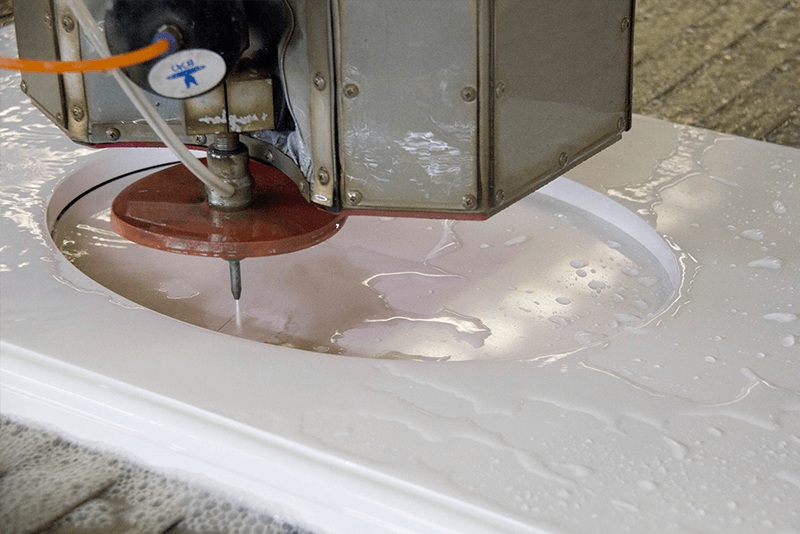

03、Water jet cutting basin hole

Rongguan quartz stone countertop basin hole is cut by water jet . Its main feature by using special emery powder for water instead of the traditional rigid grinding wheel. The working principle is the water jet from the pressurized pump, through the high pressure pipe, and then jet out from the cutting nozzle injection. The precision of water jet cutting can be limited ± 0.1mm.

The water jet machine is set by touching screen for data and function. After setting all the data and functions, the machine set in accordance with the parameters of the automatic feed and loss compensation, to ensure accurate size specifications.

Water jet machine is the most commonly processing equipment for different shaped plate, with high precision, processing any curve to meet the demands of different shapes in high production efficiency.

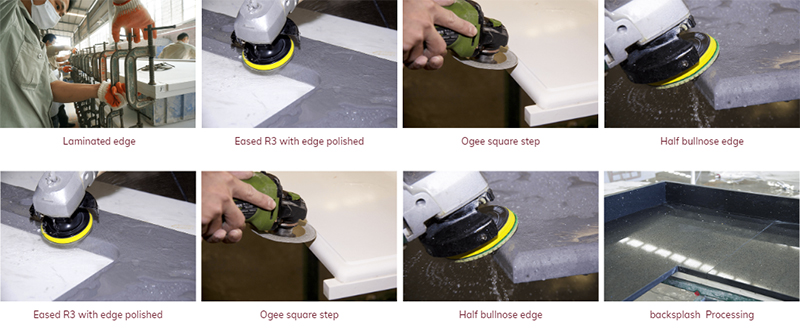

04、 Quartz countertop edge polishing machine

Our company owns two sets of polishing machines for processing edge from Italy. The types of edge include straight edge, beveled edge, bull nose edge, semi-bull nose edge and round edge. This machine has special custom-made high-quality grinding wheels, in order to avoid making the edge of stone material uneven or broken. The advanced technology in this industry outstands through the finished products with perfect flatess and glossiness of edge.

This machine can polish quartz of the thickest 100mm . It’s simple and easy to operate, stable for product quality. Its uniqueness, professional ensure that the product's internal physical quality and external aesthetic effect.

05、 Edge processing

At present the demand for quartz stone is increasing. The largest demand is There are many kinds of technology for special-shape. Special-shape has various products, and edge processing is big part of it.

Rongguan quartz stone processing workshop introduces a series of processing equipments,which process kinds of countertop to meet various demands of individual from coustomers and designers.

06、Quality control

Our company’s product quality control and test is in strict accordance with the requirements of ISO9001:2008 quality management system.

The finished counter top need to go through the instrument inspection and manual inspection. Each panel needs to be strictly inspected for the size, specification and glossiness. For the combined table top, in addition to the smoothness of edge and flatness of the panel fit the standard, also pay attention to the color and pattern unification and tight joint of different parts, the left and right side which should be in accordance with the drawings.

Unqualified products are absolutely not allowed for loading.

Strict testing system has been formed that quality competition is the core of our company's culture.

07、 Packaging

Rongguan has a set of packaging solution for the counter top.

The counter top passed quality inspection will be moved to the packing area vertically by forklift to prevent fracture.

To prevent scratching, each piece of counter top should be covered with plastic film for protection.After the label is affixed on the board, the number must be checked again.

After all confirmed, the counter top will be packed into wooden crates of export standard to make sure the panels safe. Every package is affixed a label to be distinguished.

08、Loading process

For each batch of loading, the warehouse needs to develop a plan according to the quantity and volume of the loading products to determine the size of the container.

Before loading, warehouse staff should check and confirm the order and the batch number.

While loading, the wooden crates must be fixed tight to make sure not easy to be damaged. In case of rain, to use a plastic film on top of the wooden crates. To use wooden bars between the crates to ensure the safety of products during transportation.

During loading, warehouse staff should take photos for record when the container door is open, semi open and closed. Also the staff will take photos of the key number, container number, license plate number and container seal number for record.