As a classic and beautiful floor decoration material, terrazzo flooring is widely used in commercial buildings and residential projects because of its advantages such as durability and flexible design. However, with the rise of the concept of sustainable construction, resource consumption, material waste and environmental impact in the construction process have become the focus of people's attention.

So, does the construction process of terrazzo flooring generate a lot of waste? This article will conduct professional discussions from the aspects of construction principles, material use, construction technology, waste treatment, etc., and deeply analyze its environmental protection and waste generation.

Basic Overview of Terrazzo Flooring

Before discussing the waste problem, it is particularly important to first understand the basic structure of terrazzo flooring and its construction process.

Composition of Terrazzo

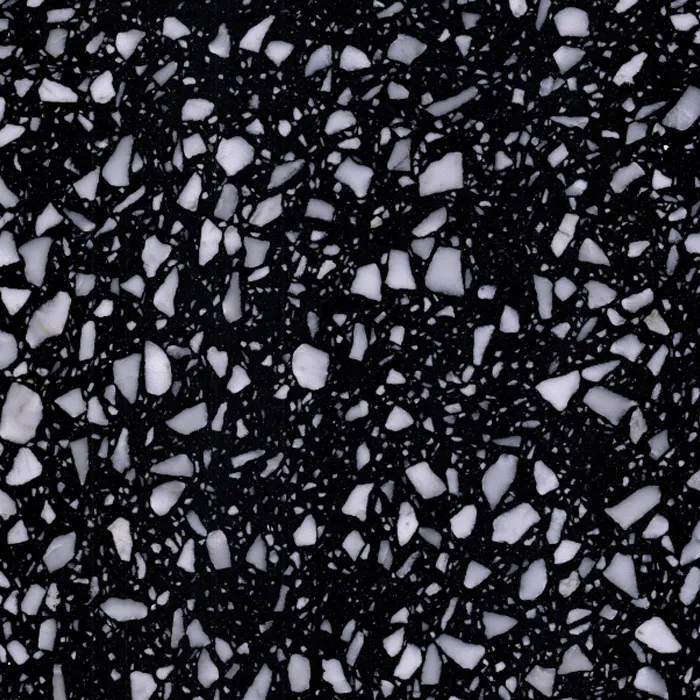

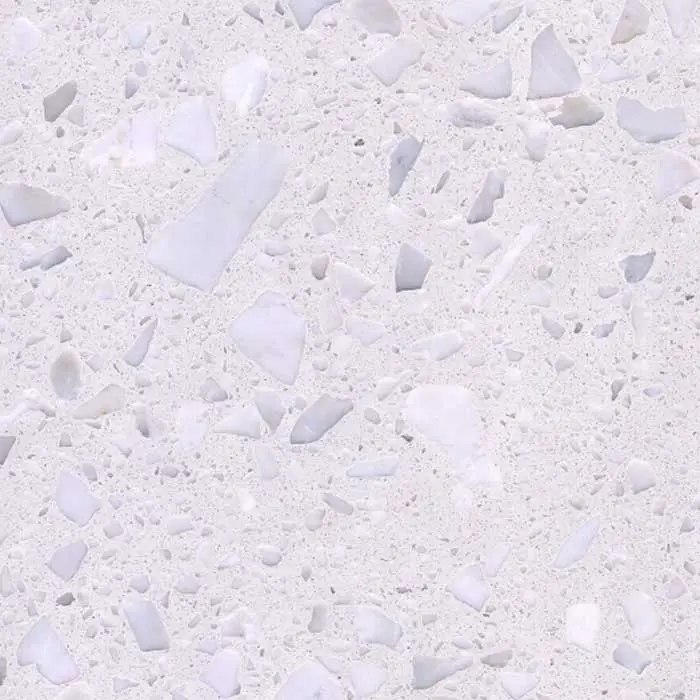

Terrazzo flooring is a mixture of various components, mainly including cement, natural stone fragments, pigments, aggregates, etc. These materials are mixed, spread, solidified, polished and polished to form a smooth and highly wear-resistant floor. Terrazzo can be divided into two categories: cement-based terrazzo and resin-based terrazzo, of which cement-based terrazzo is more common.

● Cement-based terrazzo: cement is used as the base material, mixed with stone fragments (such as marble, granite, etc.) and other aggregates.

● Resin-based terrazzo: epoxy resin or other polymers are used as the base material, and stone fragments, pigments and aggregates are added.

These raw materials are reasonably proportioned and laid on the ground as needed, and then the final floor effect is formed through processes such as grinding and polishing.

Overview of the construction process

The construction of terrazzo flooring includes multiple links:

1. Base surface treatment: Before laying terrazzo, construction workers need to treat the foundation to ensure that the surface is flat and dry, which lays the foundation for subsequent material laying.

2. Spreading and compaction: According to the design requirements, the cement-based or resin-based terrazzo mixture is evenly spread on the ground, and the compaction process is used to ensure its uniform distribution.

3. Curing and grinding: After paving, it is necessary to wait for the material to solidify. After solidification, it is polished several times to obtain a smooth surface, and finally polished to enhance its beauty.

This process involves a lot of material mixing, paving and subsequent polishing operations. Whether waste is generated in large quantities is closely related to these steps.

Sources of waste during construction

After understanding the construction process of terrazzo flooring, we can analyze the sources of waste and their properties from different construction stages. Waste mainly comes from the following aspects:

Waste in the material preparation stage

Before the construction of terrazzo flooring begins, the construction party needs to prepare a large amount of cement, aggregates (such as marble chips), pigments, stone powder and other materials. The ratio of these raw materials needs to be strictly controlled, but in actual construction, some material waste may occur. Mainly including:

● Inaccurate ratio: During the mixing process, if the operation is improper, the deviation of the ratio of cement or aggregate may cause some materials to be unusable. This kind of waste is common in construction, especially in large projects, where excessively prepared materials are likely to become redundant waste.

● Transportation and storage losses: During the transportation and storage of construction materials, due to improper operation or environmental factors (such as moisture and exposure), some materials may be damaged or deteriorated, and eventually cannot be used for construction.

Although the generation of this part of waste is relatively scattered, in large-scale construction projects, if it is not properly managed, it may accumulate and form considerable waste.

Waste in the paving stage

During the paving stage of terrazzo floor construction, the efficiency of material use and the rate of waste generation directly affect the environmental protection of the construction.

● Excess paving materials: During the paving process, construction workers need to evenly lay materials according to the area and design thickness of the ground, but because the construction is difficult to be completely accurate, there is often an over-paving phenomenon. Excess materials cannot be recycled and reused, and are often treated as waste.

● Edge waste: During construction, some complex edge areas require additional processing, which may produce irregular excess materials. Especially in customized design, terrazzo areas with different colors and patterns require more delicate paving, and edges and transition areas are prone to produce waste that is difficult to reuse.

Waste from grinding and polishing

The grinding stage of terrazzo floor construction is one of the most concentrated links in waste generation. In this step, workers use professional grinding tools to grind the floor several times to make the surface reach the predetermined flatness and finish. The waste generated during the grinding process includes:

● Grinding chips and dust: Due to the high-speed operation of the grinding tools, the stone particles, aggregates and cement matrix in the terrazzo are all ground into fine dust and particles. These grinding chips cannot be used again in construction and can only be treated as waste.

● Grinding fluid waste: In order to reduce the dust pollution generated during the grinding process, grinding fluid or water is usually used for dust reduction at the construction site. These liquids mixed with terrazzo dust need to be recycled after grinding and are part of the construction waste.

Although the waste generation rate in the grinding stage is high, the volume of these wastes is relatively small, mainly dust and liquid waste.

Analysis of the actual situation of waste generation

Although some waste will be generated during the construction process, compared with other floor decoration materials, terrazzo construction waste is relatively small, and it can be further reduced by optimizing the construction process and material management.

Efficient use of materials

The materials of terrazzo are mainly composed of natural stone fragments and cement, etc. These raw materials can be used more efficiently during the construction process. Most terrazzo projects use quantitative proportioning technology to minimize material waste. For example, in modern construction, precise calculations and mixing equipment can ensure that every part of the material can be fully used, reducing the waste caused by excessive proportioning.

Treatment methods for scraps

Scraps generated during construction, especially those caused by excessive cutting or paving, can often be handled by re-mixing, filling or as filling materials in other areas. This allows the actual waste rate of materials to be significantly controlled even in complex construction projects.

Reduction of grinding waste

Although dust and grinding waste generated during grinding and polishing are unavoidable, the impact of dust on the construction site environment can be greatly reduced by using advanced environmentally friendly grinding equipment and vacuum cleaners. In addition, the water or grinding fluid used in the grinding process is usually centrally treated after the construction is completed to ensure that the waste liquid is not directly discharged into the natural environment.

Treatment and recycling of waste

Even under the most optimized construction conditions, terrazzo floor construction will still produce a certain amount of waste. Therefore, the treatment and recycling of waste has also become an important aspect of assessing its environmental impact.

Recycling of waste

In terrazzo construction, some waste, such as stone powder or cement waste generated during the grinding process, can be recycled as raw materials for other building materials. For example, the stone powder after grinding can be used as a filling material for concrete or cement products to reduce resource waste. In addition, the scraps and gravel generated during the construction process can also be used in other floor or wall decoration projects, thereby reducing the overall waste.

Treatment of waste liquid

The water or polishing liquid used in the polishing process should not be discharged directly after mixing with dust and fine particles. Under environmental protection requirements, the construction team usually uses filtering equipment to treat the polishing liquid, separates the recyclable solid particles, and then treats the wastewater to ensure that it meets the emission standards. This method not only reduces the impact of waste liquid on the environment, but also recycles water resources to a certain extent.

Institutionalization of waste management

The management of construction waste is increasingly valued by the construction industry. Many large-scale terrazzo construction projects will formulate detailed waste management plans before starting construction to ensure that every link in the construction can minimize material waste and classify waste for recycling. This not only helps to reduce waste generation, but also saves material costs for construction units and improves construction efficiency.

When it comes to sourcing construction materials, Foshan Rongguan is a name that stands out. With over three decades of experience, we offer an impressive range of terrazzo flooring, quartz stone surfaces, and customized marble slabs. Our cutting-edge technology and dedication to quality ensure exceptional results for every order. Buyers can enjoy factory-direct prices, bulk discounts, and reliable international shipping. Contact us today to discover how our high-quality products can meet your project needs at a low cost.