Terrazzo stone flooring has become a popular choice for many public places and home decoration due to its durability, economy and beautiful decorative effect. However, there are some misunderstandings about the raw materials of terrazzo stone flooring and its relationship with marble. Some people think that terrazzo stone flooring is made directly from marble, but is this view accurate? This article will answer this question from a professional perspective, and discuss in detail the composition, manufacturing process, and connection and difference between terrazzo stone flooring and marble.

What are the components of terrazzo stone flooring?

Terrazzo is a composite decorative material, whose main components include aggregate, cementitious material and pigment. The following are the core components of terrazzo stone flooring:

1. Aggregate

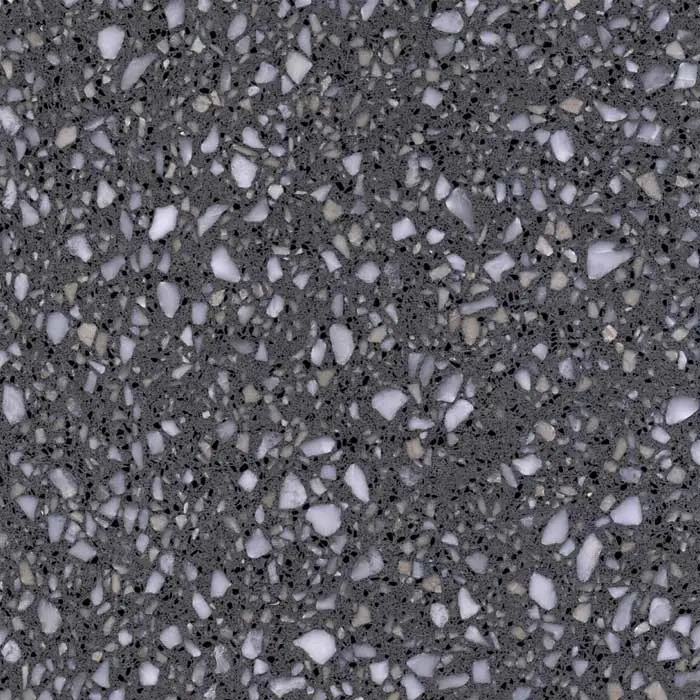

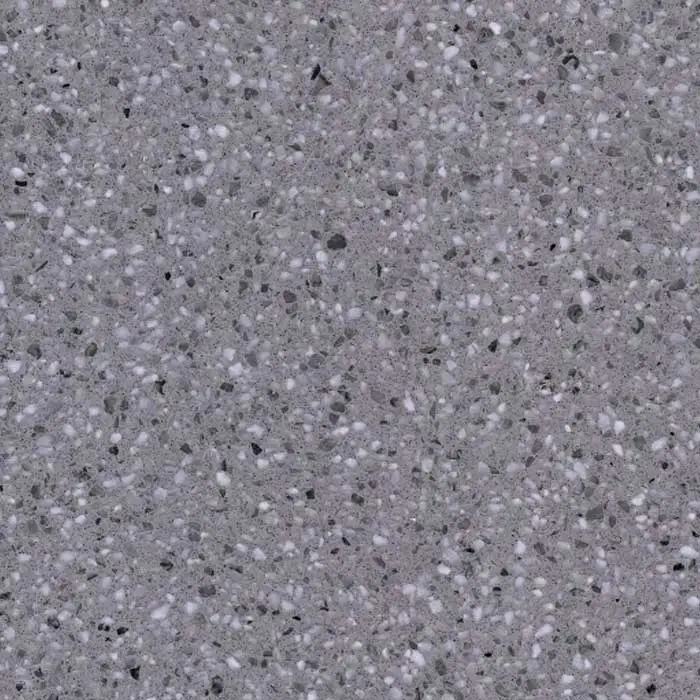

Aggregate is the main component of terrazzo stone, which determines its physical properties and appearance texture. Usually, aggregate is composed of the following materials:

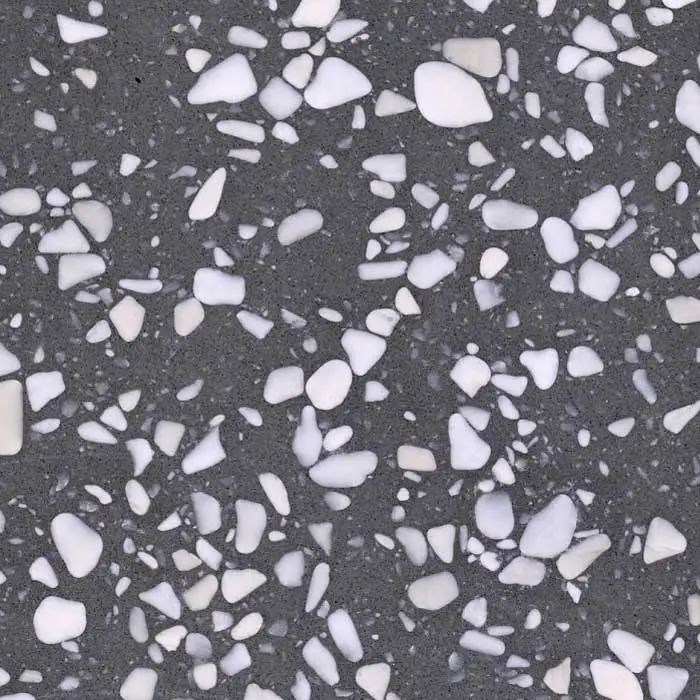

● Natural stone fragments: including fragments of marble, granite, quartz and other stones. Marble chips are one of the common aggregates, but terrazzo stone is not entirely made of marble.

● Glass particles: used for decorative needs, providing rich colors and luster.

● Metal chips or other minerals: used for special design effects.

2. Cementitious materials

The cementitious materials of terrazzo stone flooring are used to bond aggregates together, and their selection directly affects the strength and durability of the floor:

● Cement substrate: Traditional terrazzo stone often uses ordinary Portland cement, which is economical and practical.

● Resin substrate: Modern processes use materials such as epoxy resin to provide higher gloss and wear resistance.

3. Pigments

By adding inorganic pigments or other dyes, the diversified color design of terrazzo stone flooring can be achieved to meet different aesthetic needs.

The relationship between terrazzo stone flooring and marble

In order to deeply understand whether terrazzo stone is made of marble, it is necessary to clarify the definition of marble and its connection with terrazzo stone.

1. What is marble?

Marble is a metamorphic rock composed mainly of calcium carbonate (CaCO₃), and its typical characteristics are beautiful texture and high gloss. Marble is widely used in architecture, sculpture and decoration.

2. The role of marble in terrazzo stone

The aggregate part of terrazzo stone often contains marble chips, especially in vintage or high-end designs. These chips are usually a by-product of the marble cutting or processing process. By mixing and compacting these chips with cement or resin, a decorative effect that is both economical and beautiful can be achieved. However, this does not mean that terrazzo stone is made entirely of marble.

3. The essential difference between marble and terrazzo stone

● Manufacturing process: Marble is naturally formed, while terrazzo stone is a man-made material.

● Composition materials: Terrazzo stone can contain marble, but it may also contain other stones or materials.

● Usage scenarios: Marble slabs are usually used for high-end decoration, while terrazzo stone is widely used in public places for its durability and design flexibility.

What is the manufacturing process of terrazzo stone flooring?

The manufacturing process of terrazzo stone flooring is complex and delicate, and its craftsmanship determines the quality and performance of the final product. The following are the typical production steps of terrazzo stone flooring:

1. Material preparation

First, the selected aggregates (including marble chips or other stones) are washed, screened and graded. This step ensures that the aggregates are uniform in size for subsequent processing.

2. Batching and mixing

The aggregates are mixed with cementitious materials in specific proportions, and the appropriate amount of pigment is added to adjust the color. This process requires precise control to ensure a uniform mix and a consistent appearance of the final product.

3. Molding or pouring

The mixed material is poured into molds or laid directly on the ground. Through a high-pressure compaction process, the aggregates and cementitious materials are firmly combined to form a dense substrate.

4. Polishing and polishing

The cured terrazzo stone needs to be polished several times to expose the surface of the aggregates and form a flat and smooth effect. The final polishing step enhances the gloss and visual appeal of the floor.

5. Surface treatment

Depending on the specific use, an anti-fouling coating or anti-slip treatment can be added to the surface of terrazzo stone to enhance its functionality.

What are the advantages of terrazzo stone flooring?

Despite the unique high-end texture of marble, terrazzo stone flooring has become the mainstream choice in many scenarios due to its own advantages.

1. Environmental protection

The production of terrazzo stone flooring makes full use of waste materials (such as marble chips) in the stone processing process, which helps to reduce resource waste and conforms to the concept of environmental protection.

2. Highly durable

Due to its dense structure and excellent wear resistance, terrazzo stone flooring can withstand long-term use in places with high traffic volume and is not easy to crack or damage.

3. Design flexibility

The color and texture of terrazzo stone can be adjusted by adjusting the type and ratio of aggregates, with almost no design restrictions.

4. Economical

Compared with whole marble, terrazzo stone flooring has a significant cost advantage while still providing similar decorative effects.

Rongguan is synonymous with quality in the building materials industry. Our product range includes durable terrazzo stone flooring, quartz countertops, and Spanish-style roof tiles, all manufactured in our ISO-certified factory in Foshan. Exporting to regions worldwide, we are proud to offer low-cost solutions, tailored designs, and promotional discounts to support contractors and distributors. By choosing Rongguan, you gain a reliable partner that prioritizes quality, affordability, and customer satisfaction. Contact us today for competitive quotes and customized options.